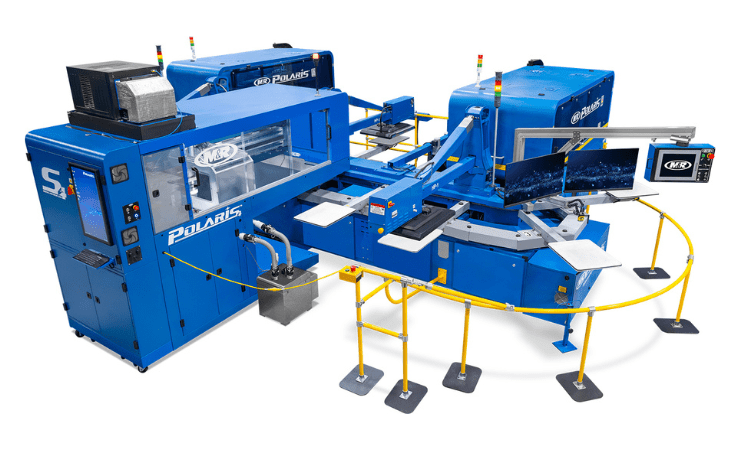

M&R Printing Equipment has unveiled the Polaris S4 pretreat unit, a “key” component of the Polaris S4 industrial DTG platform, powered by Xaar’s inkjet technology.

The pretreat unit represents a significant advancement in garment decoration technology, offering precise digital delivery of pretreat chemistry directly where needed behind each print, explained M&R.

The Polaris S4 pretreat unit features “shape for shape” area application, which ensures that pretreat is digitally targeted. The amount and density of the pretreat can also be controlled garment-to-garment via the system’s integrated workflow software. M&R CEO Danny Sweem said this breakthrough offers a more efficient production process with more garment options, a broader range of fabric types, constructions, and colours, and increased print quality, without the common risks of “boxing” or UV staining typically associated with other pretreatment methods.

The unit is the result of a collaboration between M&R and Xaar, utilising Xaar’s aqueous inkjet technology. The partnership aims to improve print quality, expand garment options, and streamline production processes.

John Mills, CEO of Xaar, added: “This project exemplifies the power of collaboration and showcases the transformative potential of our technology in the garment decoration industry.”