Epson and Japanese fashion brand Yuima Nakazato have partnered, leveraging advanced pigment inkjet printing technology on Spiber’s Brewed Protein fibre, developed using fermentation technology.

Fashion designer Yuima Nakazato will be unveiling his latest collection, featuring a blended fabric composed of 70% cotton and 30% Spiber’s Brewed Protein fibre, at Haute Couture Week on 26 June at Palais de Tokyo.

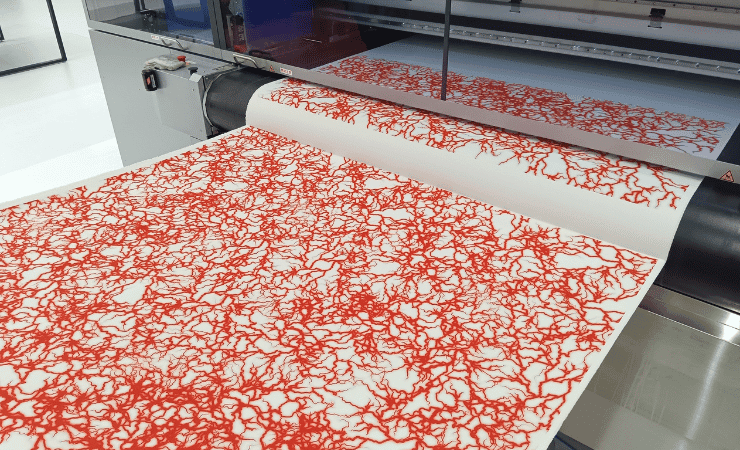

Outlined by Epson, printing on blended fabrics traditionally requires different types of dye inks, limiting the ability to achieve desired patterns and designs. However, Epson’s Monna Lisa digital textile printing technology combined with pigment inks overcomes these limitations, enabling high-resolution prints on various fabric types.

An environmentally friendly option, Brewed Protein fibre, is suited to pigment ink due to its versatility on various fabric types, whether mono or blended. This flexibility offers fabric manufacturers, brands, and designers an easier and more sustainable means of exploring new textile expressions.

Pigment inks align with the Brewed Protein material’s sustainability – they do not require steaming and washing processes after printing.

By adopting Epson’s Monna Lisa ML-13000 digital textile printing technology, water consumption can be reduced 96%. This makes pigment ink printing a more sustainable option for textile production.

Yuima Nakazato will also display a new collection of garments created using Epson’s Dry Fiber Technology and printed with pigment inks by Epson’s Monna Lisa digital textile printer (ML-13000). Epson has made enhancements to its DFT non-woven fabric, improving production efficiency and enabling the creation of wider sheets, allowing for more intricate and longer-length designs. Additionally, the non-woven fabric sheets used in Nakazato’s new collection are made from discarded fabric off-cuts sourced from sewing factories, further emphasising the sustainability of the collection, paving a way for a more eco-conscious future in fashion.