Following previews at Fespa , Ricoh has formally introduced two new direct-to-film (DtF) printers, said to allow garment and industrial decorators to ‘more simply, creatively and cost efficiently’ transform a wider variety of textiles and substrates.

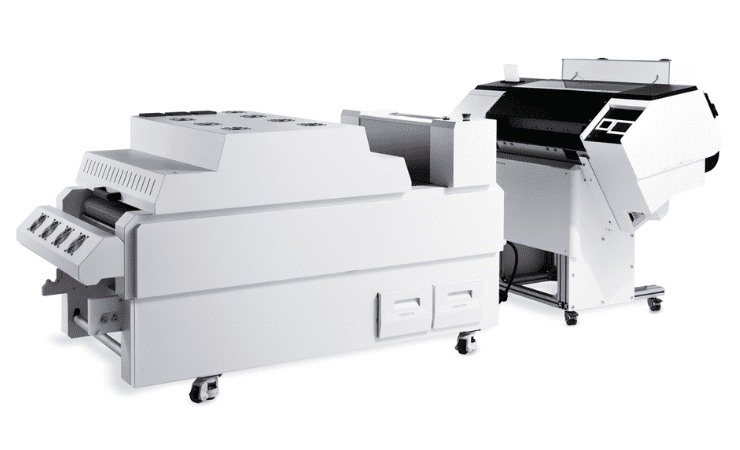

Complementing the company’s existing direct-to-garment printing systems, the Ricoh Pro DTF 10 and Pro DTF 8 are fully automated, roll-fed systems that combine water-based piezo inkjet printing with integrated hotmelt adhesive and heating in a single step. The Pro DTF 8 has eight ink channels, whilst the Pro DTF 10 has expanded colour gamut capabilities with 10 ink channels including neon pink, neon red, neon yellow and neon green. Both are Eco Passport certified.

They are powered by ColorGate’s Productionserver and also enjoy Ricoh’s end-to-end support that includes tailored software, accurate colour profiling, approved consumables and post-production processing.

Further benefits of the new Pro DTF series claimed by Ricoh include: ‘excellent’ results at high process speeds; the elimination of pre-treatment for textiles and substrates; a large selection of optimally matched consumables; no requirement for a separate dryer; and an automatic cleaning function that lowers maintenance requirements.

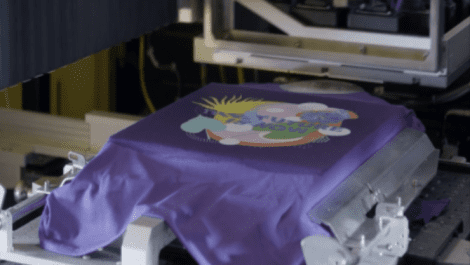

Such capabilities lead Ricoh to state that its Pro DTF 10 and Pro DTF 8, ‘offer expanded application versatility with the ability to achieve outstanding results on classic cotton and mixed materials as well as polyester, nylon, and water repellent materials such as leather and even wood.’

Axel Stuhlreiter, head of textile solutions within the Graphic Communications Group of Ricoh Europe, commented, ‘We believe the compelling innovation and performance standards that these systems offer will provide creative garment and industrial decorators with business transforming capabilities. They will also support the evolution of DtG printers, trade specialists and screen printers.’

The Ricoh Pro DTF series were previewed at Fespa Global Print Expo in May 2023, alongside the company’s DtG products, as detailed by Digital Textile Printer at the time. they are now available in the EMEA region.

Mr Stuhlreiter continued, ‘When we previewed the technology at Fespa, we were encouraged by the range of challenges that the Pro DTFs respond to, according to exhibition attendees. They included the need to manage a wide range of textile and substrate requests, produce high quality polyester and nylon workwear and sportswear, and be cost efficient when meeting varying on demand volume requests.’