Mimaki has pre-announced its ITMA focus on sustainability and the circular economy with the introduction of a pigment-based transfer printing technology that substantially reduces water use, a novel means of de-colouring dye-sub printed polyester for multiple re-use and a smaller but faster version of the Tiger600-1800TS dye sublimation printer.

The new Textile Pigment Transfer Printing System is said by Mimaki to be more sustainable than either analogue or digital textile dye printing methods, with zero water consumption and substantially lower related CO2 emissions. The system, to be demonstrated on Mimaki’s stand at ITMA, comprises three key elements: the Textile Pigment Ink, the Transfer System and the Textile Pigment Transfer paper, Texcol.

Texcol is a new transfer paper pioneered by Dutch paper manufacturer Coldenhove that allows for transferring a digital print using a three-step transfer process to create vibrant colours on a wide range of materials, including natural fibres. The design is initially printed onto the paper using a customised Mimaki TS330-1600 roll printer, using Mimaki’s new pigment inks. The paper undergoes a one-step waterless process, via an entry-level calender onto the textile of choice.

The module that adapts the TS330-1600 will be available as an option for existing and new Mimaki customers in Q3 2023 and is being previewed at ITMA. The Textile Pigment Ink is undergoing Bluesign certification for safety and environmental characteristics before commercial availability.

Mimaki is also debuting its Neo-Chromato Process, which decolourises polyester textiles that have been dyed using dye sublimation technologies. This allows materials to be re-printed or dyed immediately, contributing to a smaller circular economy. There is no limit to how many times reused polyester can be treated with Neo-Chromato and the process itself minimises water usage and pollution by enabling the disposal of the absorbent paper and decolouring solvents used in the process as burnable waste.

‘It is the responsibility of everyone here at ITMA and within the wider textile industry to enable a more sustainable future. Mimaki is actively collaborating with retail and apparel brands to explore the full potential of our latest sustainable technologies. While these latest innovations will enable significant steps forward in sustainable textile production, we also continue to focus on bringing new innovations to market that support the pressing needs of our customers, designers, brands, and importantly, the planet,’ said Arjen Evertse, General Manager Sales, Mimaki Europe.

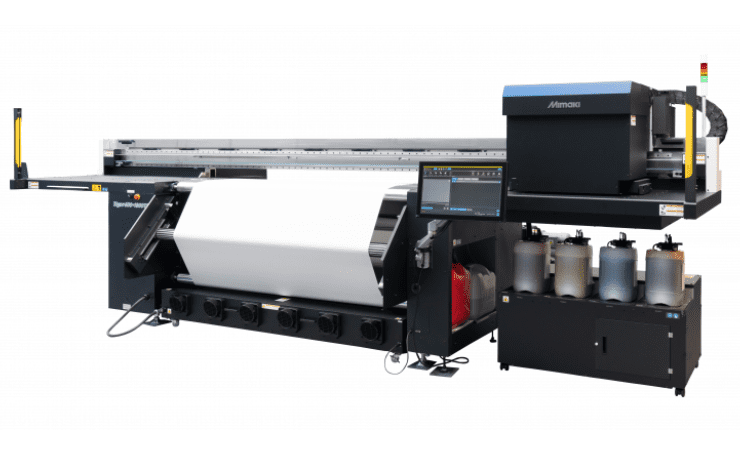

The new version of the Mimaki Tiger roll-fed printer, the 600-1800TS, boasts a maximum printing speed of 550sqm/hr (143% faster than the previous model) owing to the renovated high-speed printhead and Mimaki’s proprietary image quality enhancement technologies. The printer’s size has also been halved compared to the previous system, with the paper mounting and winding system both located at the back of the machine. This smaller footprint enables customers to accommodate multiple units to meet fluctuating demand, whilst also increasing overall production capacity.

‘All of these latest and innovative developments ideally position the Tiger600-1800TS to compete with analogue textile operations and support the move to digital print production,’ explained Mr Evertse.