Mimaki used Fespa as the platform for the first international showing of its new direct-to-film (DtF) printer, explained more about its development strategy and teased major forthcoming launches scheduled for ITMA in June.

The company exhibited the TxF170-75 DtF printer that was shown earlier in the UK at Printer & Promotion Live in February 2023. In a review of the company’s performance and plan for its current financial year, general manager sales EMEA Arjen Evertse said that Mimaki was looking for 30% growth in the textile part of its business and hinted at major announcements in this area to be made at ITMA in June, where ‘circularity and sustainability’ will be its theme.

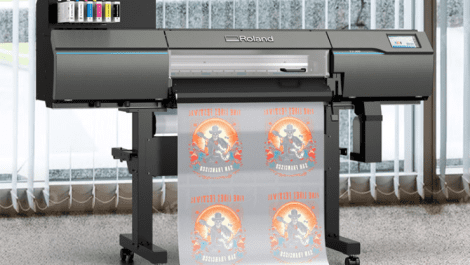

Speaking specifically about DtF, Mr Evertse said, ‘Many appreciate the possibilities, no other technology is as effective or flexible, but there have been reliability and stability issues, especially in the printing systems. Mimaki thought it could make a difference, so we took the existing 150 series, which is a proven and stable platform; the main challenge is in white ink stability so we developed a dedicated DtF circulation and new inks in de-gassed aluminium pouches, as exposure [of these inks] to air doesn’t help.’

The TxF150-75 is offered with a powder/dryer unit made by UK supplier Adkins, and the combined system supports a film width of up to 80cm as opposed to the more common 60cm. Mr Evertse explained that this is intended to minimise waste, as it will fit two typical T-shirt prints across its width, which the smaller format cannot. He added that third-party post-processing units would be available via Mimaki’s sales channels in all countries. The Adkins unit is priced at €8400 and the complete printer-plus-processor system is €21,000.

General manager marketing Danna Drion addressed Mimaki’s strategy on sustainability, saying the company was working actively towards nine of the 17 United Nations Sustainable Development Goals in response to customer requests; Mr Evertse noted that the analogue-to-digital transition generally supported this by reducing waste through over-ordering/production, stock-holding and potential wastage of outdated or unused versions – ‘[with digital] you only produce what you need,’ he said.

Ms Drion also noted that fast fashion brands are now promoting ‘sustainable’ lines and even ‘slow fashion’, based around higher value personalised garments; one Mimamki customer is even using vintage clothes to repurpose or re-manufacture. In terms of the company’s own efforts, it is switching to ‘green’ energy sources and its ink cartons have been redesigned to reduce the use of plastic. Initially being rolled out in Japan, this change is expected to find its way to the rest of the world this year. The company is also looking into offering its inks in 2l containers and considering its composition:

‘Greenguard Gold certification is increasingly being demanded’, confirmed Mr Evertse, adding, ‘but some of our machines are 15 years old and still need the old inks. We expect a phase-out of these over the next few years.’

Mimaki would not say exactly what it will be launching at ITMA but confirmed that working towards the four-yearly event had absorbed sufficient R&D resources to postpone to autumn 2023 other product launches that might otherwise have happened at Fespa.

Digital Textile Printer will be attending ITMA and will report on Mimaki’s announcements.