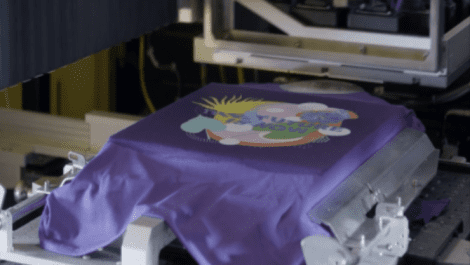

M&R, an American manufacturer of digital and screen printing equipment based in Illinois, has introduced Polaris, a new industrial, high-speed DTG printing system.

Unveiled last week during an online event, Polaris is said to set ‘a new standard with the latest generation of garment decoration technology,’ and has been developed to handle ‘a sophisticated array of automation needs and quality requirements.’

The launch event included live demonstrations of the machine, an exploration of its various features and a Q&A session with M&R executives including executive vice president Peter Walsh, innovation director Micelle Moxley and smart technology line manager Danielle Hazen.

Polaris, which M&R says has been more than three years in development, has been grown out of two previous M&R systems, the Striker and the Digital Squeegee 400. It comes with two high-speed digital print engines (one CMYK and one white) and automated pretreatment and drying systems.

Available for $824,950 (a sticker price that includes Polaris itself, as well as an installation service and training programme, a DTG consumables kit and spare parts), the system is designed to be low maintenance, takes only 15 minutes to warm up and shutdown, and can produce fully-cured printed garments in under three minutes.

Its onboard pretreatment system prepares garments in-line, eliminating storage needs for work-in-progress, and it features a built-in, high-fidelity barcode scanner that allows users to pull orders locally or from the cloud. It can switch between dark and light shirt pretreatment settings at a touch of a button and boasts what the manufacturer describes as a ‘world-class colour management solution’ that supports advanced controls for ‘accurate and consistent quality across products.’