Mimaki has lent one of its TS300P-1800 dye sublimation printers to Fogra to assist in the Geman standard body’s TextileRGB research project.

The project, which was first rolled out in the Autumn of 2020, is seeking to improve colour standardisation in digital textile printing. Intended to run for a total of two years, it is being funded by the German Federal Ministry for Economic Affairs and Climate Action BMWK.

Specifically the TextileRGB research project aims to develop a suitable RGB exchange colour space for digital textile printing and to design a standardisation concept that will result in a new ISO standard.

It is to help it achieve this goal that Mimaki Deutschland has loaned the organisation one of its TS300P-1800 dye sublimation printers, described as ‘specially designed for the textile industry.’ Mimaki says the printer delivers ‘dye sublimation prints quickly, reliably and cost-effectively,’ and that it is ‘ideal for the production of fashion and sports clothing, home textiles and POS materials.’

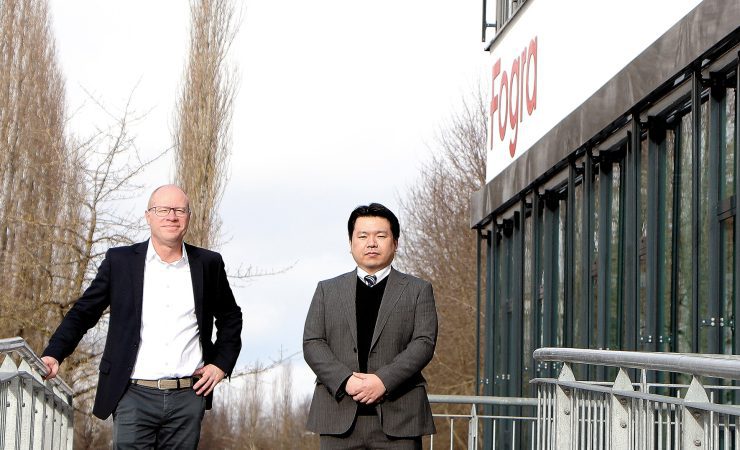

Hisashi Takeuchi, the managing director at Mimaki Deutschland, visited

Fogra’s facility in Aschheim, near Munich, to mark the official handover of the press. Whilst he was there institute director Eduard Neufeld showed him around the laboratories and the printing room, where the printer will provide valuable assistance in the practical implementation of the next project steps.

Dr Andreas Kraushaar, project manager and head of the Fogra prepress

technology department, commented, ‘We have already worked closely with Mimaki in past projects and have always been convinced of the quality of the print products. We are pleased that our cooperation is now being continued in the current digital textile printing project.’