There was a real buzz at this Printwear & Promotion Live event at Birmingham’s NEC, confirmed by the organiser who reported than in total 5167 people attended across the three days, up by 15% from 2022’s figure of 4489, showing that in-person events are very firmly back on the agenda.

There were some first showings of new equipment, and particularly in direct-to-film (DtF), which seems to be the bandwagon that everyone is now jumping on, largely thanks to DtF materials and production costs being around 10 times cheaper than embroidery, and, according to one exhibitor, ‘killing DtG’ too.

One example was Inkfuse DtF, which was offering a 30cm DtF roll-fed machine including laptop, shaker, CADlink Rip software and 100m of film plus other consumables for £7000. This machines takes about 2½ minutes to image an A3 area; Inkfuse also offers a higher priced 70cm width unit that will do the same in 25 seconds. The printers are a combination of Chinese print engines plus German mechanical engineering in the gantry that carries the printhead assembly. The faster model runs at 3040m/hr at 360 x 3600dpi.

Inkfuse’s John Hutchinson with a sample of gold DtF print

The Inkfuse systems have been two years in development, and include the company’s own inks. They offer a 52-wash guarantee for colour integrity, peeling or cracking, which is better than any other type of transfer/printing including screen print or cut vinyl, according to John Hutchinson, a consultant with Inkfuse. Another claimed strength is support for stretch fabrics, which depends on the combination of the inks, powder and curing/drying. The systems can produce quite convincing gold, silver and neon colours through careful profiling and a wide native colour gamut.

Mr Hutchinson said, ‘DtF is accessible to home users or hobbyists, 70 [breast pocket] logos can be produced for £16’.

MHM Direct GB featured on its stand a prototype 40cm roll-fed DtF machine from Brother, the 3sqm/hr GTX, to complement the sheet-fed GTX600 Pro which was shown in a ‘Hexa’ (six-colour) version, adding orange and green inks to expand the colour gamut for vivid prints.

Roland DG has its new DtF printer, the BN-20, on the Xpres stand. Roland’s head of sales – UK and Ireland Rob Goleniowski told Digital Textile Printer that he sees arrival of Roland and Mimaki as a validation of the market, saying they had been watching it but were concerned it might just be a fad; he also said that the manufacturer had learned from its resellers’ and dealers’ involvement in the sector.

Brother’s DtF prototype, expected to be launched officially later this year

Xpres also featured the new Mimaki TxF150-75 DtF machine which also seemed to be attracting a lot of attention.

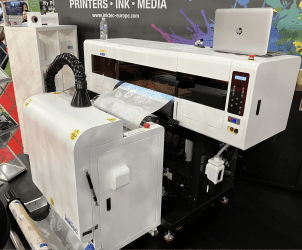

InkTec also showed a new machine, a 60cm model capable of 15sqm/hr, with an unusually small footprint of 1.8 x 2m (though sold as 2 x 2m to allow access all round), thanks to a vertically-arranged shaker/dryer unit in which the film follows a S-shaped path, and which recycles spare powder Progress through this unit takes about 10 minutes. InkTec says the curved design allows the unit’s three heating areas additional time to correctly cure the ink and melt the powder compared to other designs. Testing for washability of the finished products is in progress and no specific claim was being made on this.

InkTec has been supplying inks and films for around 18 months; the addition of its own printers enables it to supply a complete solution, which is what product marketing manager Helen Dearing said people ‘seem to want’. Two sales were made at the show, to customers who were using DtG to print their T-shirts and are now moving to DtF, according to Ms Dearing.

InkTec says consumables costs are of the order of 75 – 85 pence per square metre and the media cost is £2.60; allowing for getting 16 T-shirt prints of A4 size per square metre, the cost per garment comes out in the range of 25 – 28 pence. InkTec managing director Joey Kim noted that DtG is more expensive and a longer process, and said some sites are replacing ‘big’ DtG installations with smaller DtF ones.

Jim Nicol at TheMagicTouch also contrasted the materials costs for DtF as 65p per t-shirt with ‘pounds’ with DtG. He said targeting is key and that sending out samples is the way to develop business, ‘by getting people to realise that you can print just one’.

For higher volumes without having to make the hardware investment, Snuggle was showing its trade fulfilment capabilities for DtG, ‘3D’ via Kornit’s Max texturing capability which mimics embroidered effects, and ‘unlimited colour embroidery’ sewn thread services that integrate with e-commerce websites via an API. The variable colour thread is produced by ColorReel and allows fully graduated colours in the finished piece, though at the expense of some of the more vibrant shades that conventional dyed thread offers. It requires dedicated equipment but runs at similar speed to conventional fixed-colour embroidery machines. As it’s a trade service, it’s expected that a buyer would know which type of embroidery colour mode would be appropriate.

InkTec’s DtF machine boasts a very compact footprint for the shaker section

Resolute DtF showed examples of UV DtF for printed bottles, shoes or sportswear, using UV inks that are activated by pressure for attachment rather than by UV curing onto a substrate. They are dishwasher-proof and said to last for two years outdoors. One application example given is a seller of domestic and commercial security alarm boxes: from one set of blanks, the required branding can be printed and applied as required, rather than having to hold screen pre-printed stock. Another example is using clear ink to simulate glass embossing effects on bottles, which is said to works better than with labels.

Resolute also provided the European premiere for DuPont’s new Artistri P1600 DTF inks, which were used throughout the show, on Resolute DTF’s R-Jet Pro DTF V4 system.

Software

In addition to the proliferation of DtF machines there were also advances in software on display, both in workflow and e-commerce. Inkfuse for example featured Gangr production and workflow software designed for DtF work , while MerchBook from AimSmarter collects and feeds web orders out to a network of some 200 print service providers (PSPs)/fulfilment operations with sites in UK, eastern US, Canada and Australia.

Merchr is an e-commerce platform and fulfilment service that is recruiting PSPs to join its network and has just gained a further round of funding to expand and develop its business model.

These topics will all be examined in more depth in forthcoming articles on Digital Textile Printer.