Agfa’s Mike Horsten spoke to Digital Textile Printer about current developments in the dye sublimation textile printing sector, his own past experiences and Agfa’s present offering and likely future directions.

Mike Horsten’s involvement with textile printing goes way back to experiments in the late 1980s, attempting to make screen inks work in inkjet printers, a process that he warily admits might have broken a few printheads along the way, so his perspective on the technology is longer that most people’s.

What he has very clearly learned is that inks are crucial. ‘Even at 6sqm/hr, drying matters, as cockling of the paper in inevitable, even with a fast dryer,’ he says, noting that as things get faster, this only gets to be more of a problem in dye-sub printing, where speeds up to a hundred times faster than that are now starting to appear in digital printing devices.

At the same time, the weights of the transfer papers have been decreasing, so where he was working with 150gsm materials back in the early days, now papers are down to 25gsm or less, and even the handling of the unprinted material is an engineering challenge, though one that he notes appears to have been solved, at least based on technology on display at Fespa Eurasia in early December 2022, where 30gsm seems to have become the new standard, in Turkey at least.

‘We need to make ink for fast printers,’ he says, explaining that this leads to two interlinked requirements – less water in the ink and more colourant, which respectively should make drying easier (and therefore cheaper, a growing concern with the current energy cost rises) without sacrificing colour density and vibrancy.

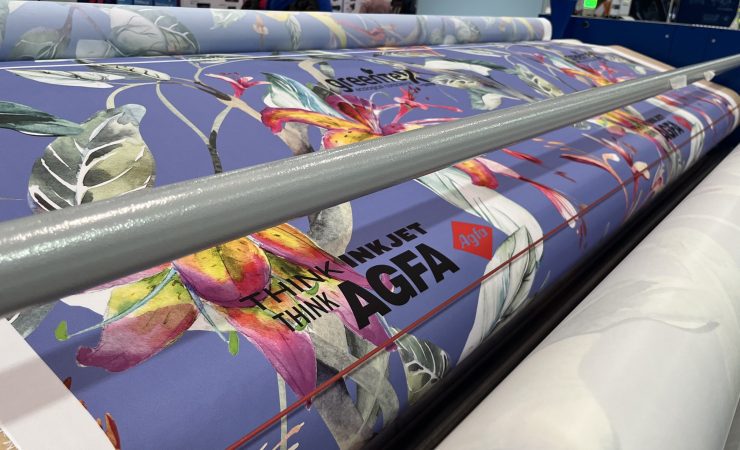

Not unsurprisingly he says that this is the challenge that Agfa has cracked with new dye-sub inks first demonstrated at Printing United last autumn, in conjunction with the company’s Avinci CX3200 3.2m roll printer, which was launched in 2021. ‘Now we can put down less ink and get the same colour and go faster without problems,’ he claims.

Cost-benefit analysis

This puts Agfa in the slightly unusual position of promoting printer-and-ink combinations that use less ink for any given amount of output. ‘Contrary to the rest of the world we’re trying to get as much out of our ink as possible. You jet very little ink but you get the high quality and the high drying speeds. You’d think that the people running the 25/30-gram paper would be totally over the [moon] with this but they aren’t, they don’t understand that when you put a higher ink load, it’s more expensive. [Our] ink becomes more expensive but the benefits outweigh the problems that you have with the cheap ink which is basically 80% water,’ Mr Horsten says.

Agfa’s Avinci 3200 is predominantly seen as a signage printer, but its inks allow for a wider range of textile applications including clothing

He adds that the low cost/high volume model favoured in parts of the dealer channel is paying more effectively to ship water, with increased stocking and printer refilling requirements, in addition to the higher energy costs of drying.

Ink pricing differences between analogue and digital print is also an apparently crucial factor for big producers, who tend to see only the difference in that one consumable cost when making the comparison between printing technologies, without necessarily considering the wider implications behind them.

Foot to the floor

Mr Horsten produced a cost comparison calculator to compare Agfa’s InterioJet flooring printer against gravure alternatives and was able to show that once the cost of cylinders and other set-up was taken into account, plus the higher usage of conventional inks against digital, the break-even point between digital and analogue was a lot higher than many users of analogue equipment thought.

While he’s quick to admit that he hasn’t done the same detailed calculation for textile printing, he’s convinced that a similar argument will apply, especially once the water and energy costs associated with conventional rotary screen printing are allocated, in addition to the screen preparation time and materials.

‘This is where digital will become a little bit more of a household name in the bigger companies because they need to change their analogue business just because of energy costs,’ he argues.

So where is Agfa going next in textile printing? While it’s too far from major shows like Fespa and ITMA to reveal anything yet in terms of new products, it does sound like evolution rather than revolution is what we may expect. Last year’s acquisition of Inca Digital did bring some high speed single-pass technology but Mr Horstern is firm that this will remain focused on folding cartons, which he also notes is ‘a lot bigger’ market than textiles. He’s dismissive of the few single-pass textile printers currently on the market:

‘Single-pass is just not ready because in my opinion if you need the volumes, you will go rotary screen. Digital is small batches, it’s diverse batches, it’s speciality printing; single-pass is going to give me the same as rotary, why should I pay extra for it?’

In terms of what we are more likely to see from Agfa, he comments, ‘We need to make sure that we bring the right inks, because I think inks are the crucial part. With our new inks we have right inks, without the harmful chemicals, with an Oeko passport which basically gives you baby and kids’ clothing, with a higher content with less water, so we are on the way for higher speeds.

‘Today we have the Avinci 3200 at 3.2m which is a soft signage printer, it’s really for the graphic industry. It’s close to our business but it’s definitely not the final part of our journey,’ he says, adding that ‘expanding the portfolio would not be a wrong statement to make’.

Mike Horsten is head of textiles at Agfa’s headquarters in Begium. He has previously worked at HP, Mimaki and ColorGate, amongst others.

Exactly how that will happen will become clearer over the coming months, with both Fespa and ITMA as major launch platforms. At the time of writing, Agfa was only booked to exhibit at the former, but Digital Textile Printer will be previewing and attending both, in conjunction with Digital Printer magazine and here on the website, so stay tuned.